Understanding Inventory Storage Systems: A Comprehensive Guide

Introduction to Inventory Storage Systems

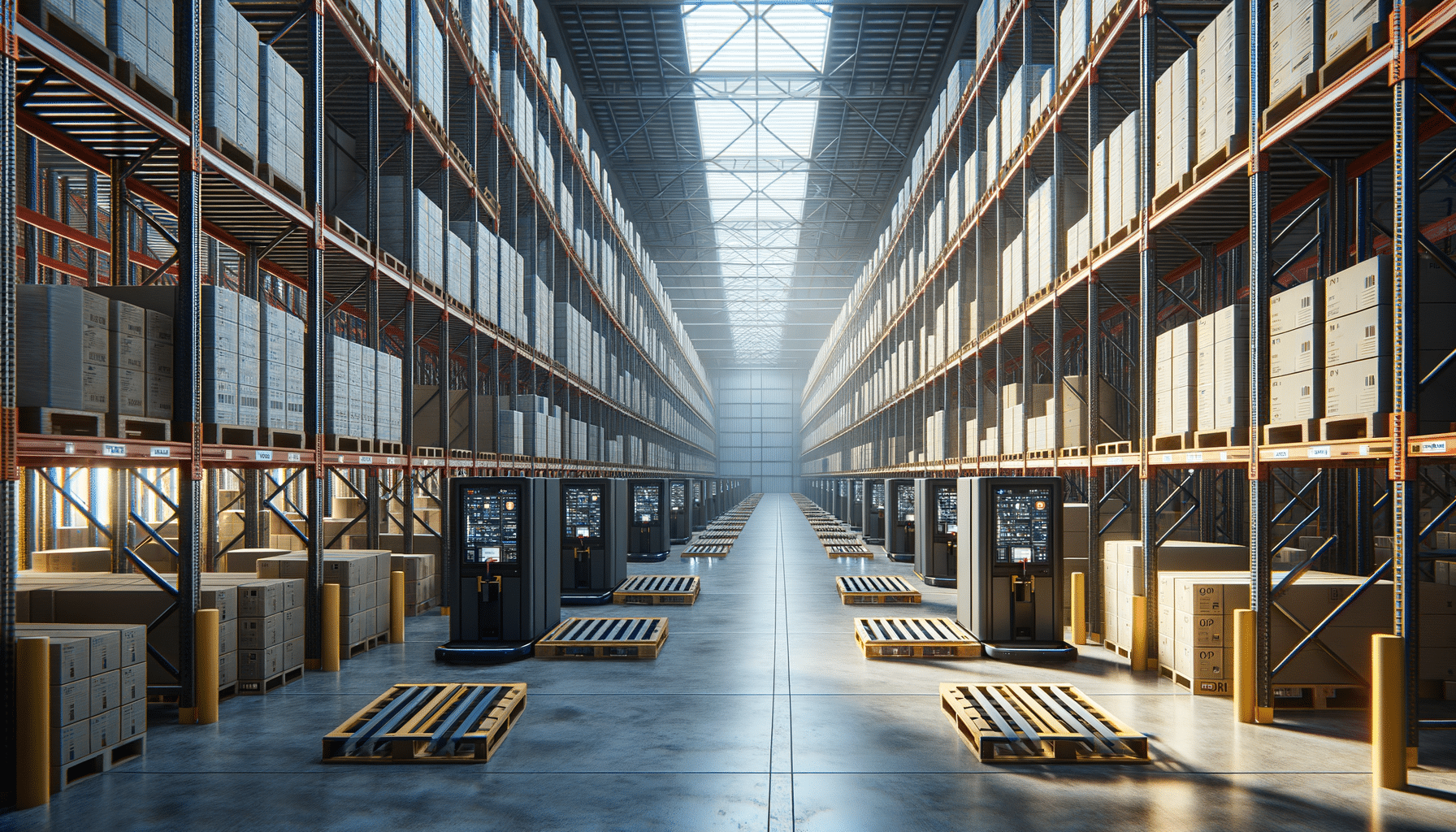

In the dynamic world of supply chain management, inventory storage systems play a pivotal role in ensuring the seamless flow of goods from production to the consumer. These systems are not merely about storing products; they are integral to optimizing space, improving efficiency, and reducing costs. With the ever-growing demands of e-commerce and global trade, understanding and implementing effective inventory storage systems has become more crucial than ever. This article delves into the various types of storage systems, their benefits, and how they can transform business operations.

Types of Inventory Storage Systems

Inventory storage systems come in various forms, each designed to cater to specific needs and operational scales. The most common types include:

- Static Shelving: Ideal for businesses with smaller inventories, static shelving is a cost-effective solution that allows easy access to stored items. It is best suited for light to medium-weight items.

- Pallet Racking: A versatile system that can handle heavy loads, pallet racking is prevalent in warehouses that require high-density storage. It maximizes vertical space and is suitable for bulk storage.

- Mobile Shelving: Designed to optimize space utilization, mobile shelving systems are mounted on tracks and can be moved to create aisles only when needed. This system is excellent for archives or storage rooms with limited space.

- Automated Storage and Retrieval Systems (AS/RS): These systems use automated technology to retrieve and store items, significantly increasing efficiency and accuracy. They are ideal for high-volume operations requiring rapid turnover.

Choosing the right inventory storage system depends on various factors, including the nature of the products, available space, and budget constraints.

Benefits of Effective Inventory Storage Systems

An effective inventory storage system can significantly impact a business’s bottom line. Here are some of the key benefits:

- Improved Space Utilization: Efficient storage systems maximize the use of available space, allowing businesses to store more inventory without expanding their physical footprint.

- Enhanced Operational Efficiency: With organized and accessible storage, employees can locate and retrieve items faster, reducing downtime and improving productivity.

- Cost Reduction: By optimizing space and improving efficiency, businesses can reduce overhead costs associated with storage and labor.

- Improved Inventory Management: Effective systems provide better visibility into inventory levels, helping to prevent overstocking or stockouts and improving order accuracy.

These benefits illustrate why investing in a suitable inventory storage system is a strategic decision for any business looking to enhance its operations.

Considerations for Implementing Inventory Storage Systems

When implementing an inventory storage system, several factors need to be considered to ensure that the chosen solution meets the business’s specific needs:

- Type of Inventory: The nature of the products being stored—such as size, weight, and perishability—will influence the choice of storage system.

- Space Availability: The physical space available will determine whether a vertical or horizontal storage solution is more appropriate.

- Budget Constraints: While some systems like AS/RS offer high efficiency, they may require a significant initial investment. It’s essential to balance cost with potential long-term benefits.

- Scalability: The chosen system should be flexible enough to accommodate future growth and changes in inventory levels.

By carefully evaluating these factors, businesses can implement storage systems that not only meet current needs but also adapt to future demands.

Future Trends in Inventory Storage Systems

The landscape of inventory storage systems is continually evolving, driven by technological advancements and changing consumer demands. Some key trends shaping the future include:

- Integration of IoT and AI: The use of Internet of Things (IoT) devices and artificial intelligence (AI) is enhancing inventory tracking and management, providing real-time data and predictive analytics.

- Sustainable Practices: There is a growing focus on sustainability, with businesses seeking eco-friendly storage solutions that minimize environmental impact.

- Automation and Robotics: The adoption of automation and robotics is increasing, enabling faster and more accurate inventory handling.

- Customization and Flexibility: Businesses are looking for storage systems that can be easily customized and reconfigured to meet changing needs.

These trends highlight the need for businesses to stay abreast of technological developments to maintain competitive advantage and operational efficiency.

Conclusion: The Strategic Importance of Inventory Storage Systems

In conclusion, inventory storage systems are a cornerstone of efficient supply chain operations. They offer numerous benefits, from improved space utilization to enhanced operational efficiency, which can significantly impact a business’s success. As technology advances and market demands evolve, businesses must continuously assess and adapt their storage systems to remain competitive. By understanding the different types of systems available and considering key implementation factors, businesses can create a robust inventory management strategy that supports growth and sustainability.